Food packaging machines straight from the manufacturer and 10-40% below market price

Manufacture of packaging equipment of various capacities depending on your technological conditions, given productivity, budget

About packaging machines

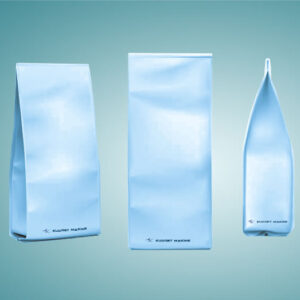

There are two types of packaging machines: horizontal and vertical packaging machines. Both are used for packing different products. Our company manufactures and sells both types of packaging machines.

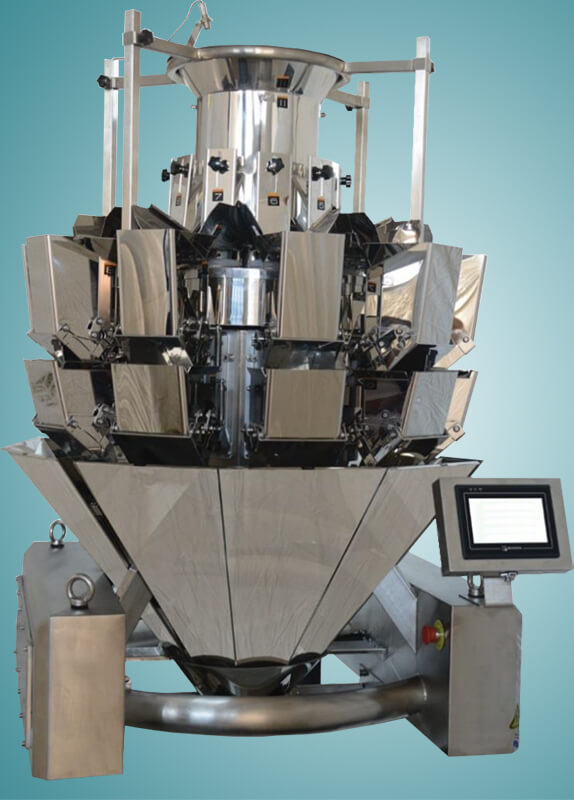

Vertical packaging machines

are used for packaging various products (food and non-food) in packages of different styles, which are formed by a packaging machine from a roll of film.

The direction of movement of the film on the tube of the packaging machine is vertical – down.

Vertical packaging machines work in two different directions:

- Intermittent motion for normal speed;

- High-performance continuous motion designed for high-speed requirements.

Kudret Makine packaging machines are the first in Turkey in their mechanics, digital electronics and technology. Efficiency is the most important aspect of Kudret Makine packaging machines. They can be designed in any required size. Thus, it is considered evidence of seal quality, effectiveness and weight sensitivity. They work in compliance with strict security measures and are designed for round-the-clock work.

They are suitable for different types of filling systems; multi-head scales, linear scales, volumetric dosing systems, screw loading devices.

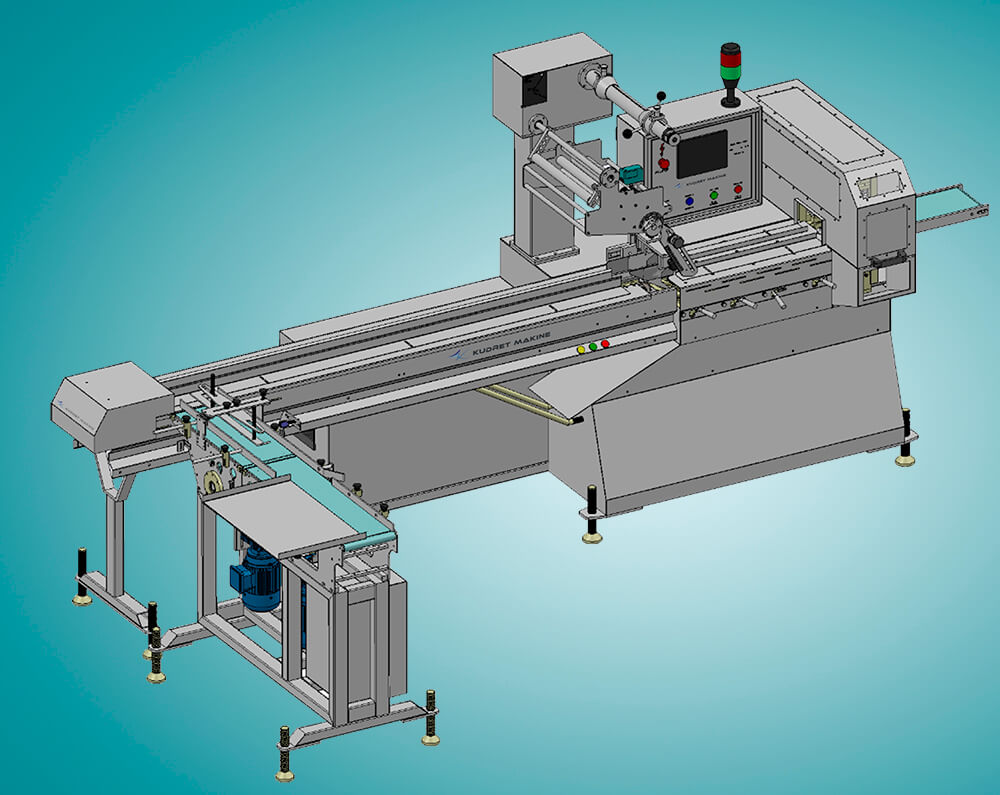

Horizontal packaging machines

are designed for packaging tall and narrow products of various sizes.

Horizontally packing machines are arranged on the principle of horizontal placement of the main parts of the machine, feed mechanism, shaper package and trim system. The machine uses the principle of flow packaging “Flowpack”. With a single packaging scheme, there are many technical solutions.

The technology for producing packages is approximately the same: a sleeve is formed from a film roll into which a product is fed using a feeding device, then the package is cut.

The flow-pack machine is suitable for packaging products in a Correx backing, group packaging of wafers, food and non-food products.

Productivity is from 100 pieces. up to 500 pcs. per minute.

Thanks to the use of two frequency-controlled drives, it became possible to set length parameters and packing speed via the PLC controller interface. This solution allows you to reduce the amount of marriage and improve the quality of packaging.

Additionally, it is possible to equip the machine with a thermal sensor, a labeling machine, a gas filling function, a stainless-steel case, etc.

All other possible additional modifications of packaging equipment on behalf of the customer.

Our production facilities and big expertise allow us to manufacture confectionery production lines. If you want to launch confectionery production we can also offer you:

Packaging types

The full brochure of confectionery equipment

Find an equipment that suits you best and see full description of it

*Downloading time: 5 seconds

Kudret Makine manufactures and sells confectionery production equipment worldwide.

- Our equipment works any type of energy source, economical and easy to operate.

- We keep it fair, you get the production equipment straight from the manufacturer, without additional markup — hence you buy below market price.

- We work with clients on any budget. From small businesses to large industrial corps including exporters. When manufacturing our production equipment we focus on the unique needs each customer.

- We are enhancing market standards by proving that confectionery lines are not necessarily expensive. We have various options for machinery— from economical models to multifunctional, pre-programmed models with multi tasking capabilities.

realized

projects

years at the market of confectionery equipment

cities use

our equipment

times improved production technology

Kudret Makine is leading Turkish company manufacturer of confectionery equipment using European quality. Our company provides a wide range of design, installation and maintenance services. Our own manufacturing facility is equipped with all the necessary machines, mechanisms and devices. Working with us, you will forget about the constant replacement of equipment, which will save your budget in the future!

Why is it worthy to work with us

INSTALLATION AND TRAINING

commissioning works services of highly qualified experienced technologists for any period

OUR PRICES ARE 10-40% BELOW THAN MARKET PRICES

our own manufacturing facility and a large assortment

DURABLE MATERIALS

stainless steel AISI 304 and AISI 316

"ISO / CE"

certificates

SAFE AND ECONOMICAL

you will reduce 30% of the operational expenses per month due to electricity savings. Overload and short circuit protection

DELIVERY

logistics and customs clearance